Hot Plate welding is a kind of original thermoplastic joining procedure with heating principle, which applies object in high temperature to melt two thermoplastic workpieces at the joining area, after which keep pressing the two parts contacting together at the molten area under pressure until become re-solidified and form fusion. During hot platen welding, the two workpieces are held firmly.

Hot Plate welding is a kind of original thermoplastic joining procedure with heating principle, which applies object in high temperature to melt two thermoplastic workpieces at the joining area, after which keep pressing the two parts contacting together at the molten area under pressure until become re-solidified and form fusion. During hot platen welding, the two workpieces are held firmly.

The workpieces to be welded is called as plastic halves of part/products, and the object in high temperature used to melt plastic halves is hot platen, while the object holding plastic half is called as hot plate welding jig or hot plate welding fixture. Normally, we call hot platen and hot plate welding jig together as hot plate welding tooling or hot plate welding mould.

Hot plate welding is a kind of the most mature thermoplastic joining articles. Because of its stability and high ability of welding performance, it is most applied for some thermoplastic joining in challenge requirement and parts specification, especially can be applied to weld parts which is over than ultrasonic welding ability.

Hot platen thermoplastic joining can be applied in many kinds of industries, such as vehicle industry, home-appliance industry, etc, especially it is applies the mostly in vehicle for the assembly of tail lamp, washer tank, fuel tank, air-duct, fuel filler pipe, glove box, etc.

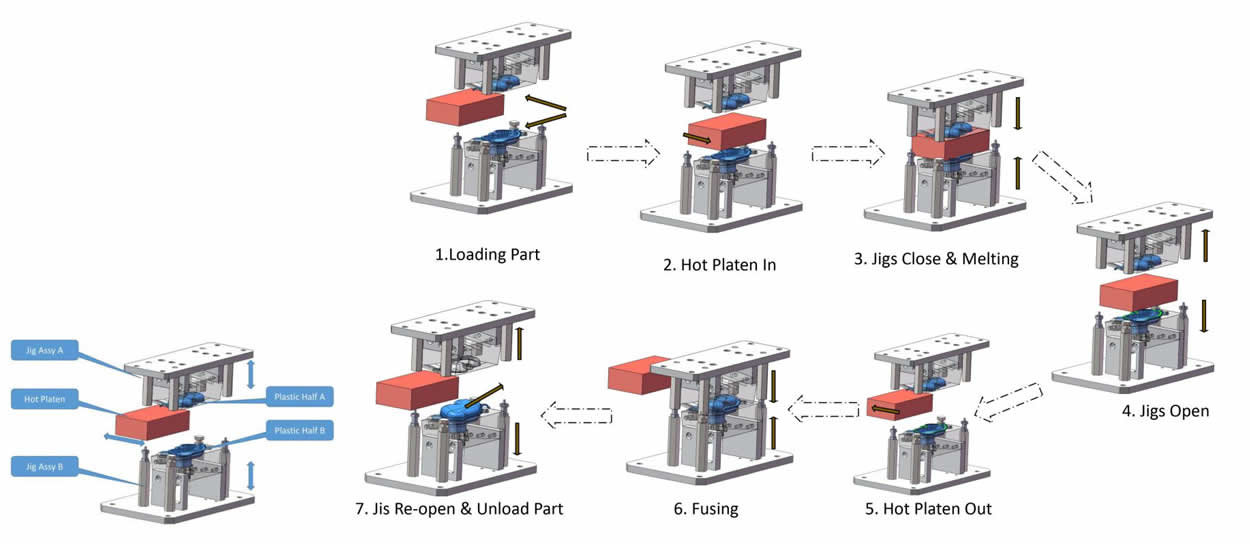

1. Loading Part: Load plastic halves into hot plate welding fixtures;

2. Hot Platen In: Hot platens move forward to the space between two plastic halves;

3. Jig Close: Plastic halves move toward to hot platen forced by hot plate welding fixtures;

4. Hot Platen Melting: Hot platens melt plastic parts at the joining area (called as joining line);

5. Jig Open: When melding is enough (normally controlled by time), two plastic halves move apart from hot platen by fixtures;

6. Fusing: Hot plate welding fixtures move toward each other and keep the two molten plastic halves contact together at the molten area under pressure;

7. Jigs Re-open: When the fusing time is finish (the molten material should become re-solidified), one of jig release the welded parts, and then the two hot plate welding fixtures move apart from each other;

8. Unloading Parts: remove the welding plastic part from hot plate welding fixture.