MP Sonic now provide garment production with seamless sewing technology and non-cold cutting arts, applying ultrasonic principle or others thermoplastic jointing principle.

Ultrasonic principles applied in garment industry included but not limited as below for examples:

| I. Ultrasonic spot welding | II. Ultrasonic spot seal | III. Ultrasonic sewing / Sealing |

|

|

|

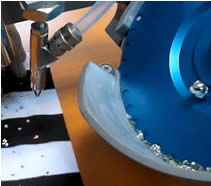

| IV. Ultrasonic roller cutting / bonding/Slotting | V. Ultrasonic Lacing | VI. Ultrasonic knife cutting / punching |

|

|

|

The most technique and equipment is applied by included by not limited as below:

| I. Underwear / Underpants ultrasonic cutting & bonding | II. Sport-wear ultrasonic sealing, cutting, bonding and vertical pressing welding | III. Windbreaker / Winter Clothes, ultrasonic welding, cutting, slotting, etc |

|

|

|

| IV. Insulation gown ultrasonic sewing / bonding (SMS) | V. Shoes vamp, insole / decoration ultrasonic welding / high-frequency welding | VI. Garment Decoration ultrasonic welding, ultrasonic lacing, etc |

|

|

|

| VII. Label ultrasonic cutting |

|

|

|

|

|