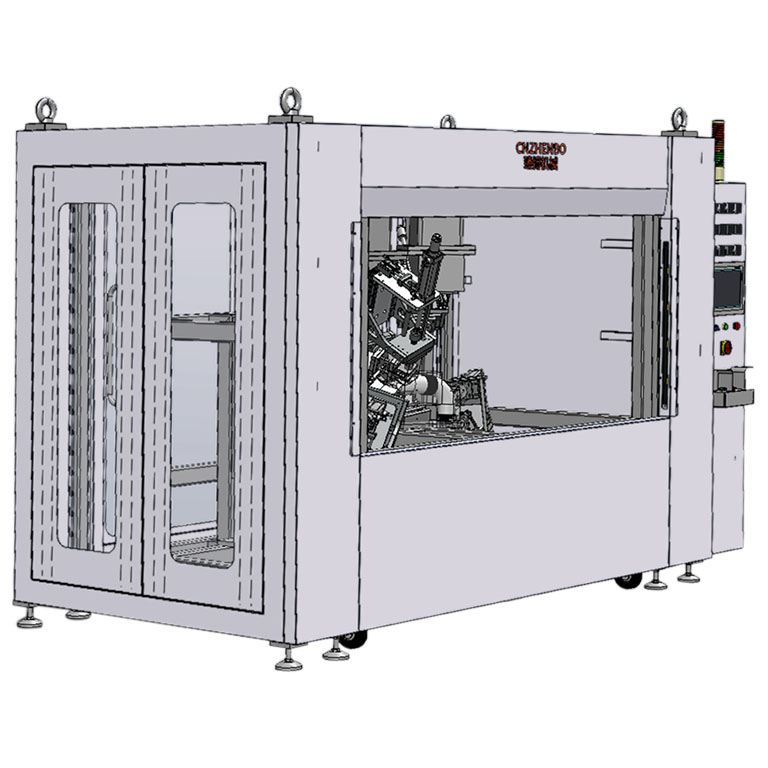

Multi-heads Heat Welding Machine

- Category:Customized Machine

- Phone:+86-15918523336

- Fax:+86-577-61517750

- Skype:

- E-mail:info@mp-sonic.com

MP SONIC designs and makes multi-heads heat welding machines for special purpose. Heating system applied to melt plastic material, it can be hot plate or infrared which is selected basing on material and welding requirement.

Multi-heads heat welding machine mostly applied for the assembly production of fuel tank system or air-inlet system, such as fuel tank welding, oil inlet pipe, air-duct, etc whose material mostly is HDPE or Nylon with GF.

I. General design concept:

1) Machine Construction, mostly it requests multiple design including multi-heads design and multi-station design basing the design of parts to be processed;

2) The index between stations normally can be rotary table, one-way direction flow or manual shifting, etc;

3) Because normally there is no support at the back of welding area, it should applied loading cell for dynamic pressure control;

4)Choice melting system basing on material, normally if it is HDPE, PP, PE, we can apply hot platen (contacting melting) , if it is Nylon, it is better by IR for non-contacting melting.

5) The base jig design should consider the deformation of molded parts;

6) Some parts, especially fuel tank, normally requests cutting hole before welding, which should be put into consideration when welding design;

7) Pokayoke normally should be designed to this kind of machine to escape the waste of material cased by operation with parts missing.

II. General Features of MP Sonic Multi-heads Heating Machine:

1)CNZHENBO | MP Sonic special designed PID temperature controlled system, temperature control result is in high accuracy in stability;

2) Adjustment in X-Y-Z direction and angle adjustment is available to fit for parts deformation;

3) Sturdy machine frame design ensure stability in precision for long duration.

4) High precision control;

5) Intelligent management of pumper punching & welding process;

7) I-Cloud remote service system applied for quick service in lower cost;

8) Multiple safety protection system for human and machine safety;

9) Sensor detection to ensure pumper and brackets loaded in right position.

This kinds of machine is specially designed basing on customer requirement and parts design, please send us your 3D data and requirement in detail before quotation.