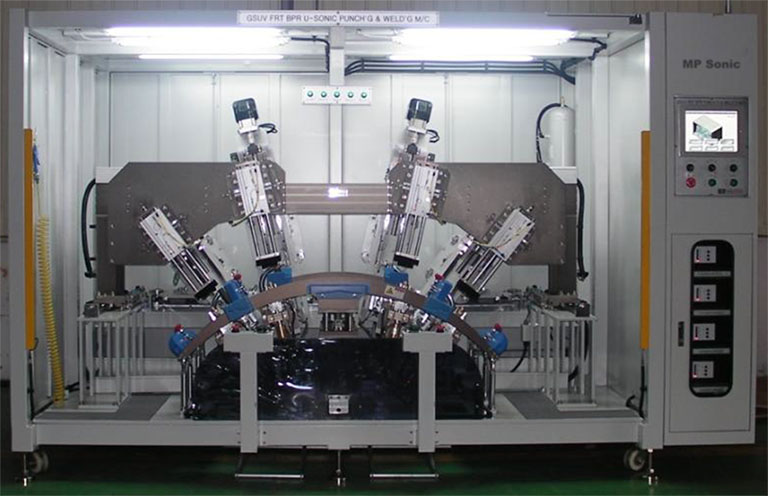

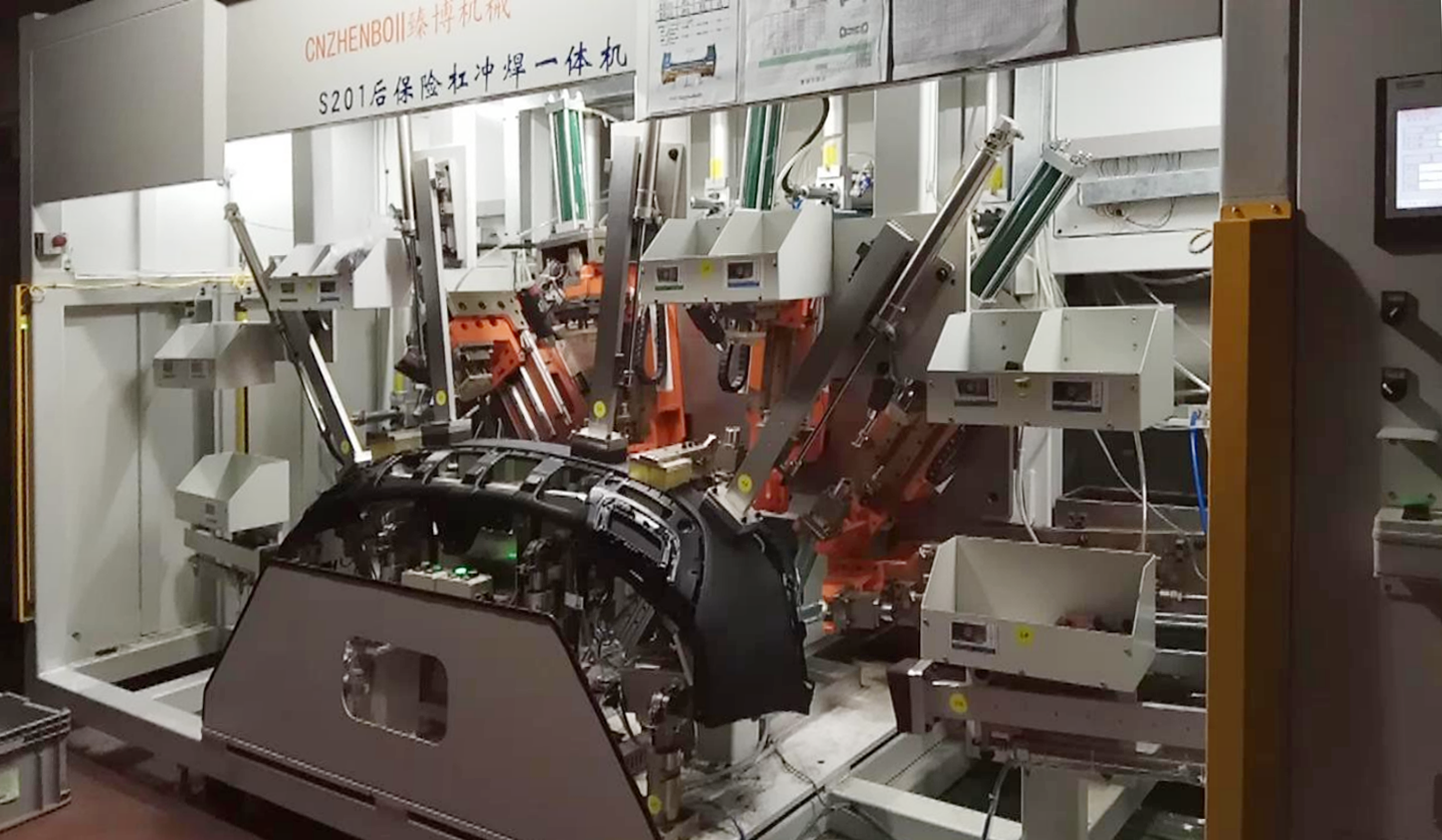

Automotica Bumper Punching & Welding Machine

- Category:Customized Machine

- Phone:+86-15918523336

- Fax:+86-577-61517750

- Skype:

- E-mail:info@mp-sonic.com

FASCIA punching & welding machine is a kind of equipment for automotive bumper finishing, which is applied to punch hole for radar, fog lamps etc and weld the bracket for radar, fog lamp, etc.

FASCIA punching & welding machine normally should be specially designed basing on requirement of each projects. Depends on the requirement, material of bumper and assembly process, the punching can be finished by hard-mechanical tooling or ultrasonic tooling, and the welding normally should be finished by ultrasonic. The forcing of punching normally can be servo motor controlled or booster-cylinders, while the ultrasonic welding normally forced by pneumatic cylinder systems.

I Main Features of MP Sonic FASCIA Punching & Welding Machine

1) High precision control;

2) Advanced ultrasonic system applied for stable and perfect process result;

3) Intelligent management of pumper punching & welding process;

4) I-Cloud remote service system applied for quick service in lower cost;

5) Stable machine fabricated for long time duration;

6) Multiple safety protection system for human and machine safety;

7) Sensor detection to ensure pumper and brackets loaded in right position.

II. General Technical

1) Power Source: 220V 1P AC 50/60Hz;

2) Air Source: 0.5~0.8MPa;

3) Ultrasonic system for welding: 35KHz 1200W;

4) Punching Procedure: by Ultrasonic (35~50KHz) or Booster-cylinder system.