Category:

Share to:

Description

MP Sonic Advanced ultrasonic system is designed for industrial application with high requirement. System is designed with data management system and communication system for the integration system design of production equipment line.

MP Sonic ultrasonic system is PLL design for stability of power output. MP Sonic anti-resonance ultrasonic system achieves strong ultrasonic output under high loading. System HF control is 1 to 4 designed which means one generator can control max 4 sets of welding units (means 4 PCs of converter) in the same frequency range.

This system can be applied for ultrasonic staking or ultrasonic spot welding to plastic, or ultrasonic cutting, punching, scoring, etc.

Catalogue of MP Sonic MSP-AS Ultrasonic System:

Ultrasonic plastic welding including energy director type ultrasonic welding, ultrasonic spot welding, ultrasonic staking (ultrasonic riveting). Ultrasonic welding is in advantages of high welding efficiency, high joining strength, possibility of welding in airtightness and easily realized in automation.

The specification of ultrasonic system, means the ultrasonic frequency and power output, should be selected according to the material, measurement and geometric shape design of parts to be welded.

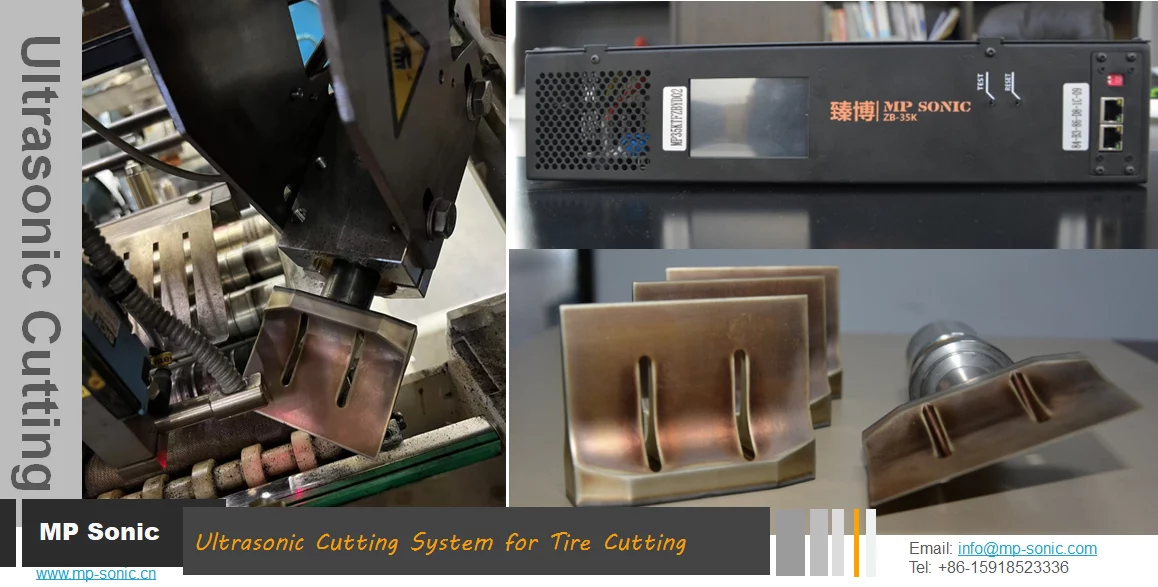

Ultrasonic cutting means applies ultrasonic energy case oscillation of cutting blade to realize fast & neat cutting. Ultrasonic cutting can be widely applied in industrial production, food production, garment production, medical & healthcare consumable production, packing, etc.

Different ultrasonic frequency and power output can be applied for cutting according to process requirement in detail. The cutting blade material can be titanium or steel which is selected according to the material to be cut and cutting result requested.

With the principle of ultrasonic cutting, ultrasonic scoring and ultrasonic punching is widely applied for industrial production process.

MP Sonic cutting system is welcomed for tire cutting, automotive bumper punching, rear-line scoring for airbag of automotive, cake cutting, fabric or nonwoven slitting, plastic parts edge trimming, etc.

Read more about ultrasonic cutting>>

Ultrasonic tooling, including ultrasonic convertor (means ultrasonic transducer), ultrasonic booster, ultrasonic horn / cutting blade /punching blade and base fixture. It must be noted that the frequency of ultrasonic tooling except base fixtures (base fixture not concerned to frequency) should be in the same frequency of ultrasonic generator system.

The material of ultrasonic tooling should be selected basing on requirement. The gain of ultrasonic booster and horn should be specified by the input gain and parts specification to be process (material, size, outline shaped design, etc).

MP Sonic provide professional technical solution to customers for the application of ultrasonic.