Category:

Share to:

Description

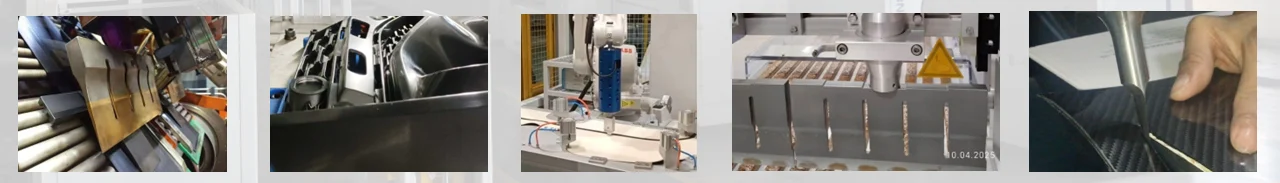

Ultrasonic cutting applies vibration in microscope level in ultra-frequency, typically 20~60Khz, to case facture on material. The vibration minimizes the friction between cutting tooling & material, achieving smooth & precision cutting to material.

The Benefit of Ultrasonic Cutting:

1.Smooth, neat and clean cutting performance;

2.Low force requested;

3.No thermal damage to material;

4.Minimized deformation to cut objects;

5.Precision in cutting control;

6.High cutting efficiency.

The application of ultrasonic cutting:

Because of above benefit from ultrasonic cutting, ultrasonic is widely applied in different industrial, especially:

Different ultrasonic frequency and power output can be applied for cutting according to process requirement in detail. The cutting blade material can be titanium or steel which is selected according to the material to be cut and cutting result requested, soundproof material cutting, tire cutting, etc;

The Critical Parts of Ultrasonic Cutting System:

1.Ultrasonic generator: the system converts supplied electric voltage in 50/60Hz to high voltage in ultrasonic frequency normally 20~60Hz and supplies to ultrasonic transducer;

Read More about Ultrasonic System:

2.Ultrasonic transducer:the converter transfer electric energy from generator into mechanical oscillation in the same frequency with piezoelectric ceramic;

3.Booster: an amplifier designed according to application to enhance the oscillation amplitude by transducer to enhance the cutting energy;

4.Cutting Blade: the sonotrode with blade designed which enhanced the oscillation amplitude and work on material to perform cutting result. Cutting blade can be titanium or steel which should be selected depends on material to be cut and cutting requirement. Material and surface process in different method to blade will help enhance blade lifetime and surface smoothness fit for challenging cutting.

Why Choose MP Sonic:

With tens experience of ultrasonic technology, MP Sonic provides customers with professional cutting solution and quality ultrasonic cutting equipment and service. MP Sonic collects information and analyze customer true requirement to gain suitable ultrasonic cutting system specification and design cutting tooling to ensure excellent cutting result, comprehensively consider and analyze different factors, such as cut material, cutting measurement, cutting quality standards, operation efficiency, including ultrasonic frequency, power, the gain and amplitude calculation, the booster and blade design, choose cutting blade material and treatment methods, etc.

Besides ultrasonic cutting systems or cutting blade, MP Sonic also designs and builds automatic or semi-automatic cutting equipment line for customers. MP Sonic designs ultrasonic cutting applied equipment in precision control meeting high requirement