Spin welding is a kind of joining technique that utilizes friction occurring at the contact surface between two work-pieces. Because it applies rotation to case friction, spin welding is known as rotation friction welding or rotation welding. Spin welding can achieve hermetic joining in efficiency & reliability. During spin welding, one work-pieces is in stationary while the other work-pieces is rotating around its own axis as the rotation center, simultaneously, external pressure forces two work-pieces in tight contact, casing temperature rising due to which melting to material at the friction area. When the molten material reach to the desired volume, machine system stops rotation and maintains the pressure forcing two work-pieces until molten material cools down and re-solidifies, thereby the welding is completed.

Spin welding is applicable to both thermoplastic material and metal material. Spin welded products must have circular cross-section at the joining interface which allows unhindered rotation. Spin welding method is welcomed due to the advantages of high operation efficiency, cost-effectiveness and exceptional welding result.

High operation efficiency

Spin welding friction time normally less than 10S, enabling rapid production cycle;

Reliable welding result

spin welding achieves welding in strength and air-tightness, ensuring durable joining;

Economical welding cost

Spin welding requests no additive or other consumable material, reducing material expense;

Easy in operation

no skilled operator requested, and automatic production can be realized;

Lower maintenance & equipment simplicity

Minimal equipment investigation and maintenance cost.

The rotation of spin welding is typically driven by electrical motor or pneumatic rotator. Electrical motor achieves high speed and high torque output, which is suitable for welding parts in varies size from small to big, in contrast, pneumatic rotator is ideal for the welding of small parts requesting low rotation torque.

The critical is that electrical motor realizes more reliable in control than pneumatic rotator, stable output of electrical motor can be controlled by electrical circuit design easily, in contrast, pneumatic rotation is sensitive to the change of the external air pressure or flow which leads to leading to potential inconsistencies.

What’s more, electrical type spin welding can realize orientation welding with servo motor or step motor, but it is impossible by pneumatic rotator.

1.Rotation speed (Angular Speed VS. Circumference Speed)

Angular speed (rpm) is the primary reference of rotation speed, while circumference speed (mm/s) is critical to ensure sufficient frictional energy to melt material, because melting depends on friction, a minimum motion distance in limit time must ne achieve to generate enough heat.

To control circumference speed, the rpm must be adjusted based on the diameter of the welding area. Normally larger diameter requests lower rpm for the same linear velocity.

Eg. For a small part welding, high angular speed requested to ensure enough circumference speed, while a larger part welding requires lower angular speed to avoid excessive heat buildup.

2.Rotation torque

A critical technical parameter ensures effective rotation against frictional resistance, which must be adjusted based on:

Diameter of the welding area: larger diameter increases rotational inertia which requests higher torque.

Weight of rotation fixture: the heavier fixtures, the higher resistance, the higher torque requested;

3.Clamping force

Ensures effective friction, material melding and bonding. The optimal applied value depends on:

Parts size and weight: the larger/heavier parts requests higher clamping force to maintain contact;

Material Properties: Softer material normally requests lower clamping force while hard material normally requests higher clamping force;

Deformation condition of parts: during spin welding, a suitable clamping force is requested to correct the parts deformation. The clamping force for deformation correction should be based on the stress or hardness of parts deformation.

Desired welding strength: stronger joint often needs higher clamping force to prevent slippage.

| Performance | Pneumatic | Step Motor | Servo Motor | Hydraulic System |

| Cost | Low | Medium-High | Medium-High | High |

| Force Output | Low | Medium-High | Medium-High | High |

| Depth Control | NG | Medium | High | High |

| Consumption | Pressure Air | Electric | Electric | Electric + Oil |

| Stability | Low | Medium | High | High |

| Maintenance Cost | Low | Medium | Medium | High |

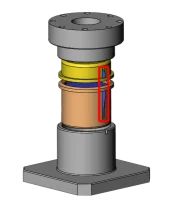

MPS-T3KTP is a spindle friction welding machine designed by CNZHENBO | MP Sonic in high speed rotation friction for thermoplastic jointing in small diameter.

Spin welder MSP-B75TP is a specially designed welding machine for child carrier wheel by rotation friction.

Spin welding is a kind of frictional joining technique in capability of producing strong, air-tight welding to parts with a circular-axis jointing, which with high bond strength / hermeticity requirements. During spin friction welding, one part half is held stationary in a holding fixture while the other one is rotated against it under pressure at a high speed normally 80~1600 rpm, which results friction at the touch area of two part halves (means the joining area) and causes the joining surfaces to melt until form fuse together, after which stop rotation and keep two part halves together under pressure until the interface of the jointing area cool down and become solidification.